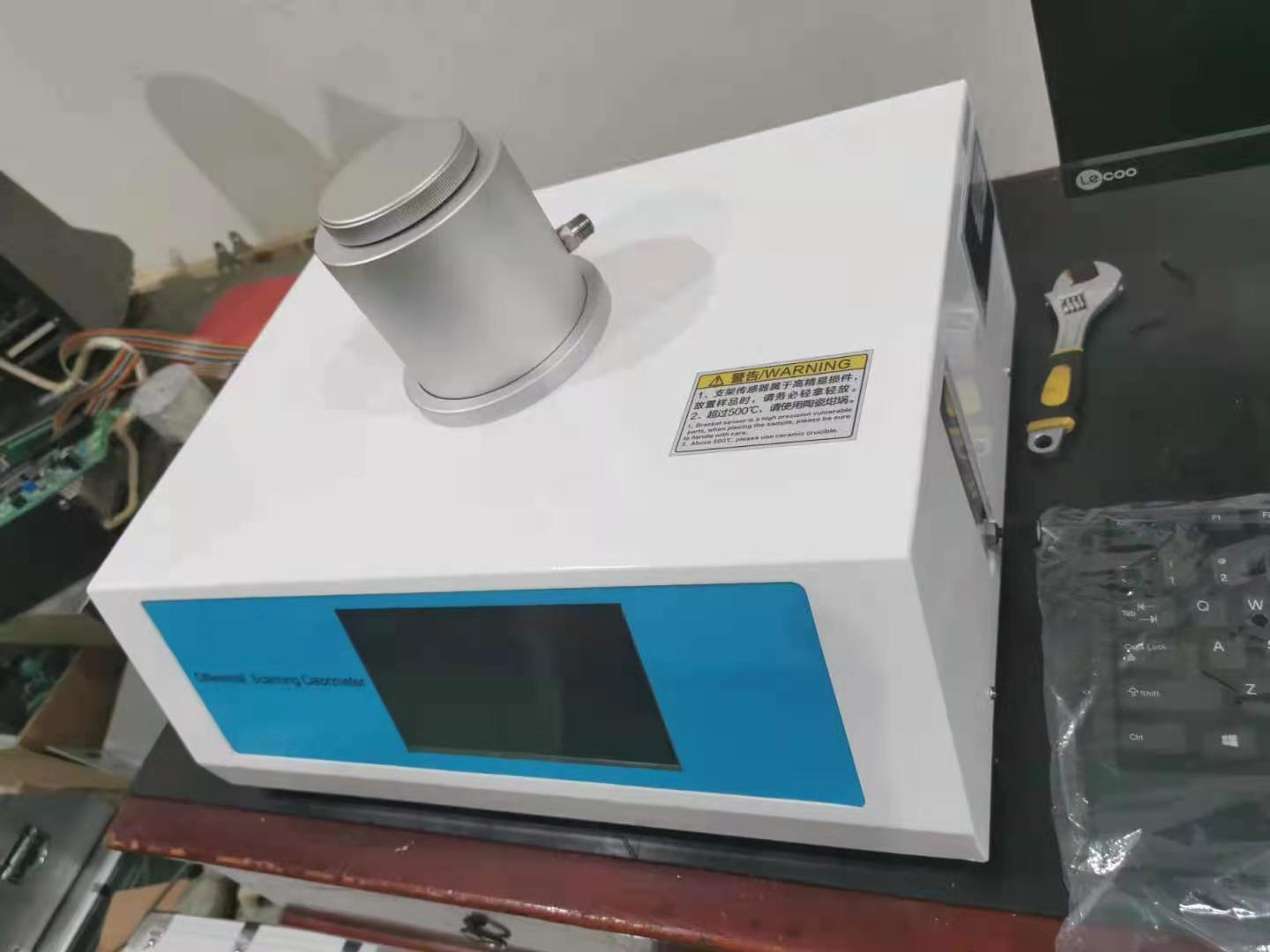

DSC-500BS DSC Differential Scanning Calorimeter

NO:Touch Screen, Oxidation induction time test and Melting point test, Temperature range : 10 °C ~ 500 °C, Water CoolingWe"re here to help:

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

DSC-500BS Oxidation induction time test and Melting point test

Temperature range : 10 °C ~ 500 °C, Water Cooling System

1. Simple Introduction and Applications

1: Differential scanning calorimeter, which measures the relationship between temperature and heat flow related to the internal thermal transition of materials, has a wide range of applications, especially material development, performance testing and quality control. The characteristics of materials, such as glass transition temperature, cold crystallization, phase transition, melting, crystallization, product stability, curing / crosslinking, oxidation induction period, etc., are all research areas of differential scanning calorimetry.

2: Scope of application of differential scanning calorimeter: curing reaction temperature and thermal effect of polymer materials, determination of material phase transition temperature and thermal effect, crystallization of polymer materials, measurement of melting temperature and thermal effect, glass of polymer materials Transformation temperature.

2. Features

1: Supports multiple parameters such as oxidation induction period, melting point, cold crystallization, solidification, enthalpy value, glass transition temperature, specific heat capacity, etc. The customer operates with one touch, and the software runs fully automatically.

2: The new sensor sample holder has a completely closed structure design to prevent items from falling into the furnace body.

3: The instrument conforms to the following national standards, but is not limited to the following national standards:

GB / T 19466.3- 2009 / ISO 11357-3: 1999 Part 6 Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) during the oxidation induction period;

GB / T 19466.2- 2004 / ISO 11357-2: 1999 Part 2: Determination of glass transition temperature;

GB / T 19466.3- 2004 / ISO 11357-3: 1999 Part 3: Determination of melting and crystallization temperature and enthalpy.

4: Built-in 10.8-inch ultra-large industrial-level computer, no additional computer, integrated equipment, rich display information, including set temperature, sample temperature, oxygen flow, nitrogen flow, differential thermal signal, various switch states, flow return zero.

5: The right side of the instrument is equipped with four USB ports as standard, which is convenient for users to connect external devices such as mouse, keyboard, printer, U disk, etc., and is convenient for users.

6: The internal USB communication interface of the instrument is more stable and versatile than the original instrument, and the communication is reliable and uninterrupted. It supports the self-restoring connection function.

7: The gas flow meter automatically switches the two atmospheric flow rates, with fast switching speed and short stabilization time.

8: Standard samples are provided as standard, which is convenient for customers to correct the constant temperature coefficient.

9: Pre-installed software, no computer adaptability problems, reducing connection and other problems caused by replacing the computer and installing driver errors.

10: Support user self-programming program to realize full automation of measurement steps. The software provides dozens of instructions. Users can flexibly combine the instructions according to their own measurement steps and save them. Complex operations are reduced to one-click operations.

11: Configure WIN 10 system, with 32GB capacity, 2GB system memory, no need to use U disk to transfer data, the instrument can be stored inside, operation mode can be used with touch screen and mouse

12: Dual temperature probes, which detect the temperature of the furnace body and the temperature of the sample separately, to ensure the high repeatability and authenticity of the sample temperature measurement.

13: The furnace body is heated by electric wire, and the furnace body is cooled by water. The heating and cooling speed is fast to avoid the high temperature of the furnace body from damaging the refrigeration source.

3. Main Technical Parameters

Temperature range : 10 °C ~ 500 °C, Water Cooling System

1. Simple Introduction and Applications

1: Differential scanning calorimeter, which measures the relationship between temperature and heat flow related to the internal thermal transition of materials, has a wide range of applications, especially material development, performance testing and quality control. The characteristics of materials, such as glass transition temperature, cold crystallization, phase transition, melting, crystallization, product stability, curing / crosslinking, oxidation induction period, etc., are all research areas of differential scanning calorimetry.

2: Scope of application of differential scanning calorimeter: curing reaction temperature and thermal effect of polymer materials, determination of material phase transition temperature and thermal effect, crystallization of polymer materials, measurement of melting temperature and thermal effect, glass of polymer materials Transformation temperature.

2. Features

1: Supports multiple parameters such as oxidation induction period, melting point, cold crystallization, solidification, enthalpy value, glass transition temperature, specific heat capacity, etc. The customer operates with one touch, and the software runs fully automatically.

2: The new sensor sample holder has a completely closed structure design to prevent items from falling into the furnace body.

3: The instrument conforms to the following national standards, but is not limited to the following national standards:

GB / T 19466.3- 2009 / ISO 11357-3: 1999 Part 6 Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) during the oxidation induction period;

GB / T 19466.2- 2004 / ISO 11357-2: 1999 Part 2: Determination of glass transition temperature;

GB / T 19466.3- 2004 / ISO 11357-3: 1999 Part 3: Determination of melting and crystallization temperature and enthalpy.

4: Built-in 10.8-inch ultra-large industrial-level computer, no additional computer, integrated equipment, rich display information, including set temperature, sample temperature, oxygen flow, nitrogen flow, differential thermal signal, various switch states, flow return zero.

5: The right side of the instrument is equipped with four USB ports as standard, which is convenient for users to connect external devices such as mouse, keyboard, printer, U disk, etc., and is convenient for users.

6: The internal USB communication interface of the instrument is more stable and versatile than the original instrument, and the communication is reliable and uninterrupted. It supports the self-restoring connection function.

7: The gas flow meter automatically switches the two atmospheric flow rates, with fast switching speed and short stabilization time.

8: Standard samples are provided as standard, which is convenient for customers to correct the constant temperature coefficient.

9: Pre-installed software, no computer adaptability problems, reducing connection and other problems caused by replacing the computer and installing driver errors.

10: Support user self-programming program to realize full automation of measurement steps. The software provides dozens of instructions. Users can flexibly combine the instructions according to their own measurement steps and save them. Complex operations are reduced to one-click operations.

11: Configure WIN 10 system, with 32GB capacity, 2GB system memory, no need to use U disk to transfer data, the instrument can be stored inside, operation mode can be used with touch screen and mouse

12: Dual temperature probes, which detect the temperature of the furnace body and the temperature of the sample separately, to ensure the high repeatability and authenticity of the sample temperature measurement.

13: The furnace body is heated by electric wire, and the furnace body is cooled by water. The heating and cooling speed is fast to avoid the high temperature of the furnace body from damaging the refrigeration source.

3. Main Technical Parameters

| Model | DSC-500BS |

| Temperature range | 10 ℃ ~ 500 ℃ |

| Temperature resolution | 0.01 ℃ |

| Calorimetric resolution | 100%, under certain conditions, it can completely distinguish the two thermal powers that are close to each other |

| Heating rate | 0.1 ~ 80 ℃ / min |

| Cooling rate | 0.1 ℃ / min ~30 ℃ / min |

| Constant temperature | 10 ℃ ~ 500 ℃ |

| Constant temperature time | recommended <24h |

| Temperature control method | heating, constant temperature (full automatic program control) |

| DSC range | 0 ~ ± 500mW |

| DSC resolution | 0.01mW |

| DSC sensitivity | 0.01mW |

| Working power | AC 220V 50Hz or customized |

| Atmospheric control gas | Nitrogen Oxygen (the instrument switches automatically) |

| Gas flow rate | 0~ 00mL / min |

| Gas pressure | 0.2MPa |

| Gas flow accuracy | 0.2mL / min |

| Optional crucible | aluminum crucible Φ6.7 * 3mm |

| Parameter standard | Equipped with standard materials (indium, tin, zinc), users can correct temperature and enthalpy |

| Data interface | standard USB interface |

| Display mode | 10-inch industrial computer touch display, can be connected with external mouse, keyboard, USB flash drive, printer |

| Power | 300W |

| All imported sensors, imported chips | |

| Fully enclosed structure design prevents items from falling into the furnace and pollutes the furnace, reducing maintenance rate |

|

| Optional function |

2) Data network remote transmission function |

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China