WAW-F series of computer-controlled electro-hydraulic servo universal testing machine (four-column d

NO:30Ton, 60Ton, 100Ton, 200Ton UTM (four-column double screw type)Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

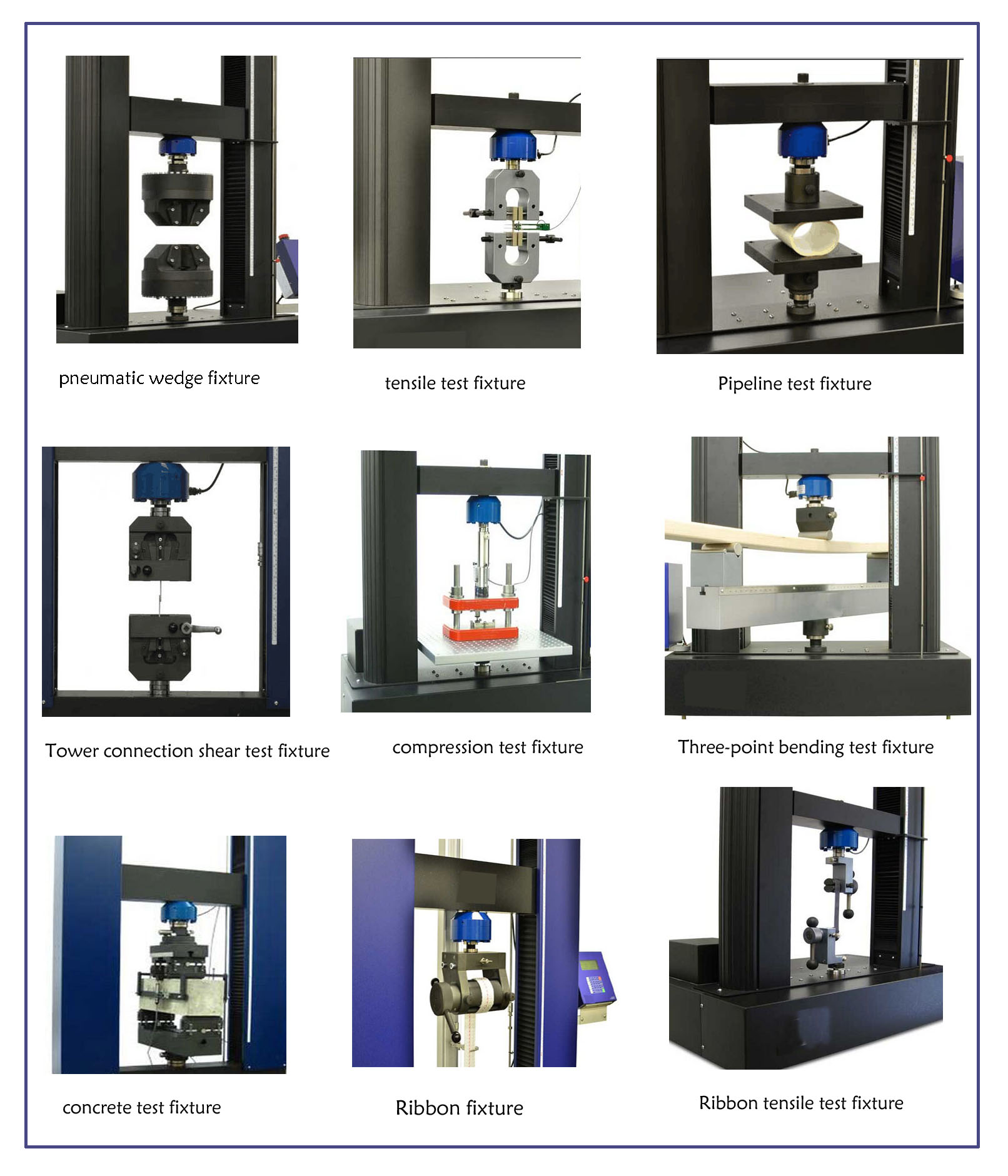

The oil cylinder mounted under the host, Gap seals cylinder, four-column, two-screw frame structure (commonly known as six columns). As a result of four-column frame structure, compression test when sample sizes bigger, and excellent stability of the host structure. Space for tensile tests on test, the test space can be used for compression, flexural and shear test (need to increase the corresponding aids). Lower beam movements using cycloid reducer, sprockets, chains, screw vice drive, to achieve tension, compression adjustment space. Main oil cylinder honing cylinders, hydraulic force sensors (precision load cell force measurement to be added, is a special configuration). Automatic hydraulic clamping system to facilitate clamping the sample, good stability. Configure the relevant test to be completed accompanied steel, metal samples, steel hinge line (the host computer changes), cables, fasteners, concrete samples.

| The main technical parameters | WAW-F Series | ||||

| 300 | 500 | 600 | 1000 | 2000 | |

| The biggest test of(KN) | 300 | 500 | 600 | 1000 | 2000 |

| Force range | 4%~100%(Or 1% to 100% precision) | ||||

| Test Force showed the relative error | Better than ± 1% of indicated value (≤ ± 0.5% precision) | ||||

| Deformation Accuracy | ±1%(Or ± 0.5% precision) | ||||

| Stretching space(mm) | 550 | 550 | 550 | 650 | 800 |

| Compression space(mm) | ≥500 | 650 | |||

| Clamping methods | Automatic clamping | ||||

| Clamping diameter of round specimen(mm) | Φ10-Φ32 | Φ13-Φ40 | Φ13-Φ40 | Φ26-Φ60 | Φ40-Φ60 |

| Flat plate specimen thickness(mm) | 0-15 | 0-15 | 0-30 | 0-40 | 0-40 |

| Shear specimen diameter(mm) | 10(Optional, non-standard) | ||||

| Upper and lower platen size(mm) | Φ160(Alternative 204 × 204) | ||||

| The maximum distance between the fulcrum bending | Optional | ||||

| Pump motor power | 1.5KW | ||||

| Beam moves up and down motor power | 1KW | ||||

| Deformation measurement device | Photoelectric encoder or electronic extensometer | ||||

| Security devices | Software protection and mechanical limit protection | ||||

Product type static hydraulic testing systems

The standard: GBT228 ISO: 15630-1,6892 ASTM: A370, C39, C469, E8 other: EN 10002-1

Owned material metal: asphalt / rock / concrete, fasteners, components

Industry metallurgical industry, quality inspection centers, universities, industrial supplies, automotive / rail / ship building, aviation industry

Test type stretching: compression, bending, shear

■ four-column double screw structure with the most reasonable working position and stress state.

■ customized according to the requirements of the sample and configure related test space can be accompanied by complete sample reinforced steel hinge wire, cable, fasteners, concrete tests■ Hydraulic clamping device can independently adjust clamping speed (configurable inching clamping device according to customer requirements)

■ You can choose according to the requirements of a load sensor or oil pressure sensor, effectively improve the test force measurement range and accuracy values.

■ fuel tank mounted under the host structure reduces the height of the center of gravity lower test to reduce the impact of the breaking machine damage.

■ can accurately measure the distance after moving beam with optical encoder.

■ integrated oil source design makes the machine more compact and reasonable, reduce floor space.

■ provides manual and automatic dual control system, choose the operating mode.

■ built-in integrated technology-based controller card, reducing wiring, improve test real-time control and real-time acquisition capabilities, improve product stability.

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China