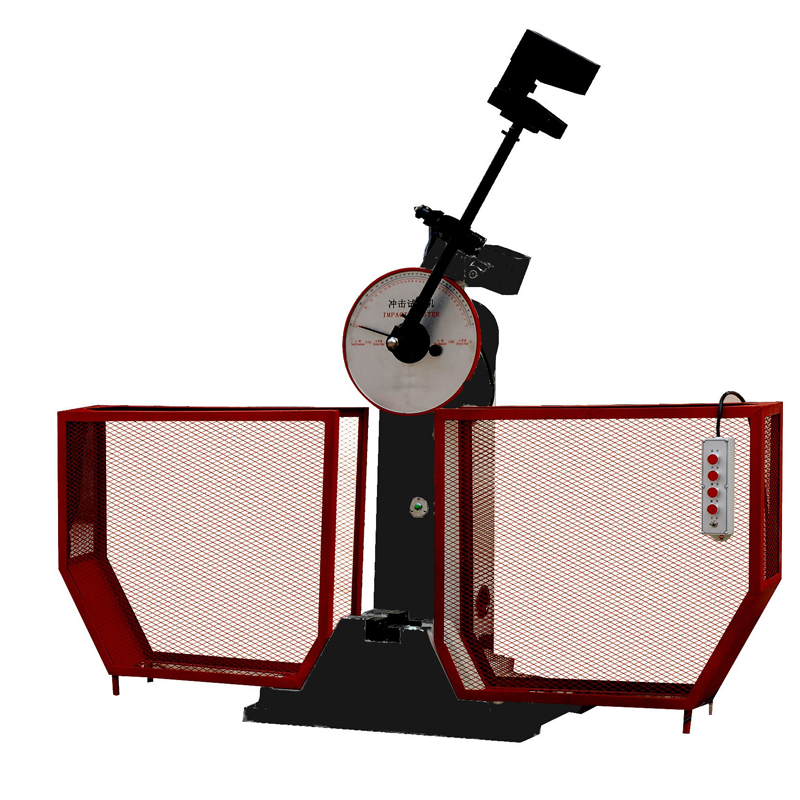

JBW-300B 300J Computer Controlled Pendulum Charpy Impact Tester

NO:150J / 300J Computer Controlled with Software impact testing machineWe"re here to help:

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

1.Application:

JBW-300B Computer Control Semi-automatic Charpy Impact Testing Machine are mainly used to determine the anti-impact capability of metal materials under dynamic load.

Carry out the functions of zero clearing and automatic return, capturing the value of lost impact energy and pendulum cycle by means of setting up with computer program,and the results can be monitored, stored and printed out. Control box or computer program control is alternative operating method.

JBW-B Computer Control Semi-automatic Charpy Impact Testing Machine are adopted by many institutes and high-tech enterprises.

It can meet test standards: ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-2007.

2. Features:

2.1 Fully automatic, sample feeding, auto position the sample; high efficiency.

2.2 Pendulum rising, impact, sample feeding, position, free releasing is realized automatically by easy PC mouse click.

2.3 Safety pin guaranties the impact action, standard protection shell to avoid any accident.

2.4 Pendulum will automatically rising and ready for next impact action after specimen breakout.

2.5 With two pendulums (big and small), PC software to display the energy loss, impact tenacity, rising angle, test average value etc. test data and result, also the curve display available, with calculation and report printing function. The dial scale can show test results too.

3. Main Technical Parameters

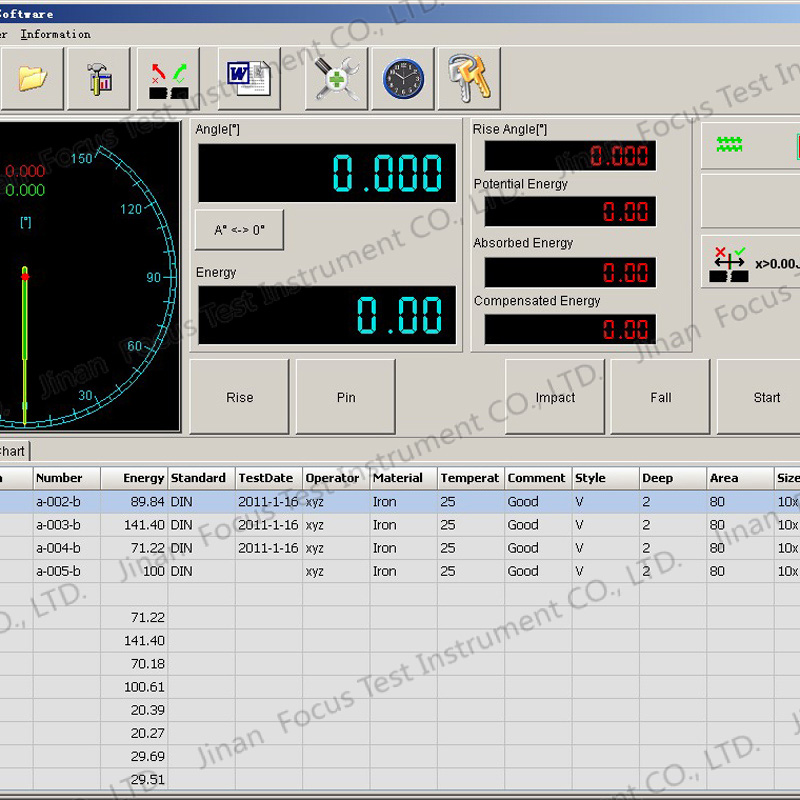

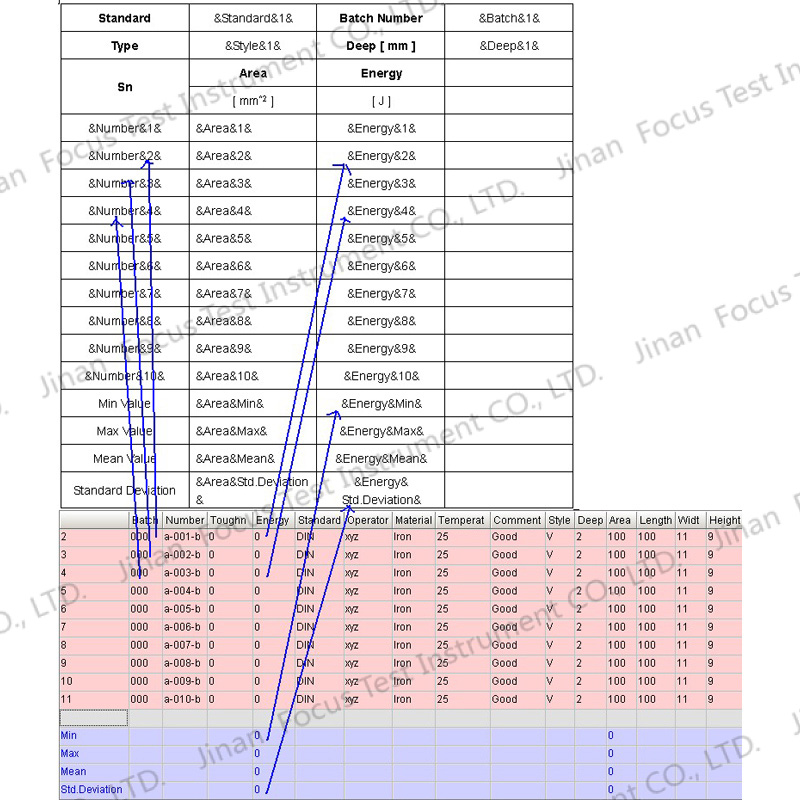

Software Interface

JBW-300B Computer Control Semi-automatic Charpy Impact Testing Machine are mainly used to determine the anti-impact capability of metal materials under dynamic load.

Carry out the functions of zero clearing and automatic return, capturing the value of lost impact energy and pendulum cycle by means of setting up with computer program,and the results can be monitored, stored and printed out. Control box or computer program control is alternative operating method.

JBW-B Computer Control Semi-automatic Charpy Impact Testing Machine are adopted by many institutes and high-tech enterprises.

It can meet test standards: ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-2007.

2. Features:

2.1 Fully automatic, sample feeding, auto position the sample; high efficiency.

2.2 Pendulum rising, impact, sample feeding, position, free releasing is realized automatically by easy PC mouse click.

2.3 Safety pin guaranties the impact action, standard protection shell to avoid any accident.

2.4 Pendulum will automatically rising and ready for next impact action after specimen breakout.

2.5 With two pendulums (big and small), PC software to display the energy loss, impact tenacity, rising angle, test average value etc. test data and result, also the curve display available, with calculation and report printing function. The dial scale can show test results too.

3. Main Technical Parameters

| Model | JBW-300B |

| Control Mode | Computer Control Automatic |

| Max. Impact Energy | 300 J / 150 J |

| Min. Reading Values | 1 J |

| Impact Speed | 5.2 m/s |

| Pre-rising Angle Of The Pendulum | 150° |

| Angle Accuracy | ±0.1° |

| Specimen Bearer Span | 40+0.2 mm |

| Round Angle of The Jaw | R 1.0~1.5 mm |

| Round Angle of Impact Edge | R 2.0~2.5 mm (Special Order ASTM E23: R8±0.05 mm optional) |

| Thickness of Impact Blade | 16 mm |

| The Distance Between The Pendulum Shaft And Impact Point |

750 mm |

| Standard Specimen Dimension | 10 mm * 10 (7.5 or 5) mm * 55 mm |

| Impact Pendulum Configuration | 150 J, 1 PC; 300 J, 1 PC |

| Host Appearance Dimensions | 2124mm * 600mm * 1340mm |

| Weight | 480 KG |

| Power Supply | 3phs, 380V, 50Hz |

Software Interface

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China